A Guide to the Different Types of Tank Jackets

Different types of fabrication plants rely on a pipe heating system to keep a room warm. In this case, the room that needs to stay warm constantly is a tank’s interior. If the inside of a tank gets too cold, the materials inside could go bad. To improve your tank’s insulation, you need a guide to the different types of tank jackets to get an idea of what tank sleeve to use.

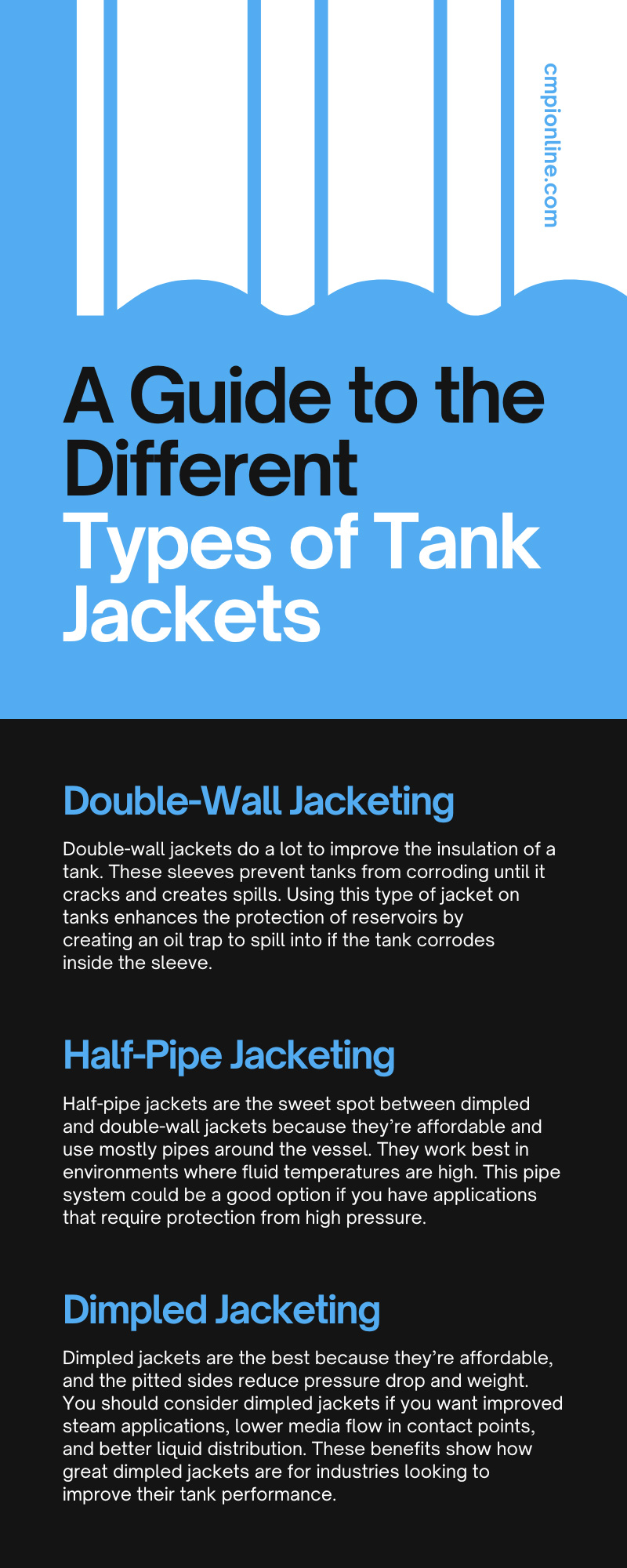

Double-Wall Jacketing

Double-wall jackets allow workers to adjust the reservoir's heating and cooling. These walls can shut down one side at a time to give more heat to one side if needed. A conventional wall is heavy and thick, helping improve the tank’s insulation.

The Benefits of Double-Wall Jacketing

Double-wall jackets do a lot to improve the insulation of a tank. These sleeves prevent tanks from corroding until it cracks and creates spills. Using this type of jacket on tanks enhances the protection of reservoirs by creating an oil trap to spill into if the tank corrodes inside the sleeve.

Half-Pipe Jacketing

A half-pipe sleeve works well for applications with higher temperatures. Since contents like oil and steam move around a lot, exterior piping helps these contents flow around the reservoir without actually interacting with the compounds.

The Benefits of Half-Pipe Jacketing

Half-pipe jackets are the sweet spot between dimpled and double-wall jackets because they’re affordable and use mostly pipes around the vessel. They work best in environments where fluid temperatures are high. This pipe system could be a good option if you have applications that require protection from high pressure.

Dimpled Jacketing

A dimpled jacket is a good choice for workers that need a case that doesn’t drastically affect the inner temperature. These sleeves are better because the sleeve dimples reduce cost, weight, and wall thickness. You should not use this cover if you work with thermal shock.

The Benefits of Dimpled Jacketing

Dimpled jackets are the best because they’re affordable, and the pitted sides reduce pressure drop and weight. You should consider dimpled jackets if you want improved steam applications, lower media flow in contact points, and better liquid distribution. These benefits show how great dimpled jackets are for industries looking to improve their tank performance.

What Is a Tank Jacket’s Purpose?

The purpose of a jacketed tank is to keep matter inside a tank at a consistent temperature without changing it too much. You could think of a tank jacket as a sleeve you’d use on clothing or a beverage cup. A shirt sleeve protects the arm from cold weather, and the case you place onto a drink prevents it from burning your hands and creating rings on a table.

You need a tank heater jacket to keep your reservoir's contents flowing without disruption or interaction with other composites. Tank jackets come in different styles for manufacturers to store their mixtures safely.

Why Are Tanks Designed With Jackets?

Engineers design tanks with jackets to improve throughput around the entire vessel, thus enhancing your product quality and machine performance. It is crucial to use a sleeve around a tank to improve the heating and cooling processes of your tank contents. Without this kind of balanced temperature control, the chemicals, matter, and other contents inside these vessels would go bad.

Reasons Your Business Needs a Tank Jacket

A tank jacket is an easy thing to apply to a vessel. Your vessels need one because the temperatures fluctuate from ongoing environmental changes. One day it could be warm; the next, it could be cold—it all varies depending on your tank's climate. If you want the best way to keep the contents of your tank safe, then using a tank jacket can help. The tank sleeve improves moisture buildup, prevents containments from leaking, and saves more money on replacing your tanks and cleaning up after a spill.

The Industries Using Tank Jackets

Many industries use tank heater jackets to store materials and protect them from inclement weather and unpredictable temperatures. These tanks are beneficial for the chemical and mining industries. Here’s a look at the other fields that benefit from using tank jackets.

Mining

Mining is a field requiring workers to work in hazardous conditions. Workers place a jacket sleeve around the pipes and tanks to avoid exposure to harmful contents in these tanks and protect the matter from fluctuating temperatures. Using a tank jacket lessens the chance of insulated fires, causing components and fluids to interact, and keeps the temperature consistent.

Chemicals

Working around chemicals is another job that creates exposure risks if workers don’t stabilize the content's temperature correctly. Using a pipe system outside the tank can stabilize your tank contents by releasing fluid or gas through the tank’s walls to help the chemicals flow. A plus side is that the contents coming from the pipe won’t interact with the chemicals.

Food Production

Food and drink production companies use preservatives to keep products fresh. The systems they usually use are stainless steel and carbon, but if you don’t perform any maintenance tasks on these machines, they could face moisture exposure, bacterial growth, and fluctuating temperatures. Workers can use jackets around their tanks to keep the contents from worsening.

Oil and Gas

Oil and gas are essential to the economy, but under the worst conditions, they could cause explosions. To avoid those explosions, you need heat jackets around tanks to keep the temperatures consistent and protect the interior components from interacting with the outside.

Create Tank Jackets With CMPI

This guide to different styles of tank jackets is a list of what you need to know when designing sleeves for your reservoirs. Working with a company with experience in designing tank jackets for your industry is a good idea. Our metal fabricators at Custom Manufacturing and Polishing, Inc have professional training and experience designing tank heater jackets that meet every customer's expectations.

Come and see what CMPI is all about. We’re a team of creatives who dream of nothing but designing products that bring a smile to your face and that you can use proudly. Come and make us your preferred dimple jacket manufacturer so you can create something thermal and keep your tank's contents safe.