Advantages of Stainless Steel for Fabrication Projects

Stainless steel is the optimal choice to work with among buyers for many reasons. When purchasers come forward with an idea, they lay out the details and their desired budget. Some even request certain metals. However, we may interject and recommend stainless steel instead of other metals because of its advantages when working on fabrication projects. It’s not dependent on one specific type of project; it lends its benefits across many project spectrums—here’s how it helps yours.

What’s Great About Stainless Steel in Fabrication?

Many know stainless steel as just a metal type, and others know the compounds that make up the material prove the strength and durability of stainless steel. The greatest thing about stainless steel is that it works in every industry, including architecture and kitchenware products.

Because of its grade, it’s considered a low-carbon alloy with at least 10.5% of chromium. Chromium is a layer that protects the metal from corrosion and defects. By having fewer spots or rust, the maintenance decreases significantly. Why else would you use this material? Find out below as you learn the advantages of using stainless steel in a fabrication project.

It Has Corrosion Resistance

Corrosion is a significant downfall for many products, leading to scrapping ideas with other metal materials and retreating to the drawing board. When a customer’s introduced to stainless steel, they’re left enchanted by the built-in chromium layer that blocks moisture buildup, which is one of many causes of corrosion.

Because this material’s loved across many industries, countless companies have enjoyed the idea of not needing to clean their metal surfacing as often since its chromium layer blocks bacteria out. Various environments can handle stainless steel, especially when around chlorine and acidic materials.

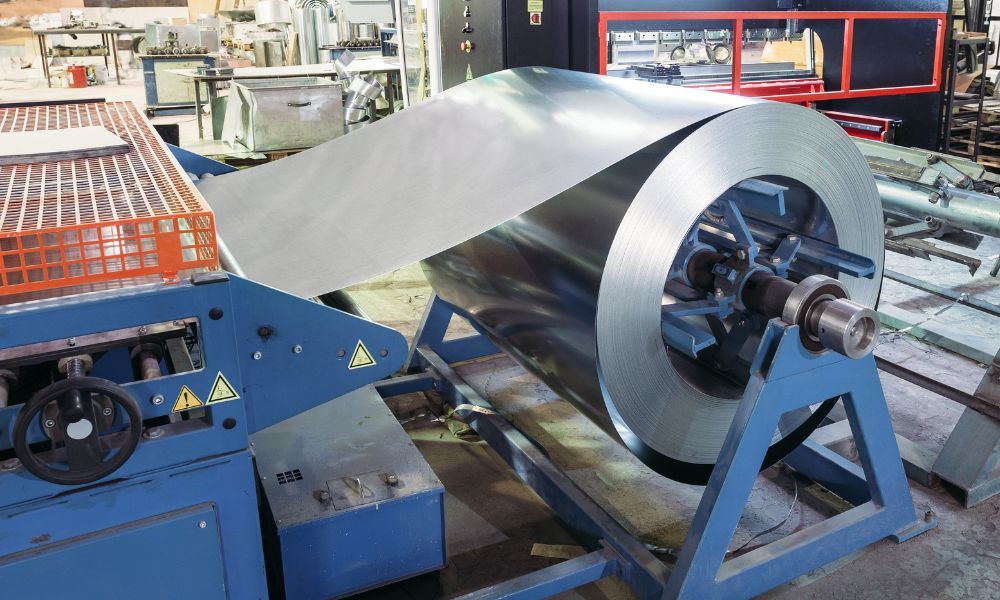

Stainless Steel Makes Fabrication Simple

Industries have project timelines that require months or years to work on, especially if they’re working with certain metal types. However, what practices do manufacturers use to ensure these metals don’t corrode over time? For some, they place a finisher on and let it dry, and then reapply it often.

Stainless steel cuts that time in half using a finisher and natural layers from the chromium content inside the material. Today, many industries need a product right away that doesn’t tarnish, so they turn to stainless steel. A polished stainless steel plate is better to use as it’s easy to assemble, and many of the grades lead to better fabrication prospects.

The Material Is Stronger

While it’s simple to use, stainless steel also has incredible strength. Many cities with modern buildings need materials that survive any weather elements, like the sun and snow. These two elements put much pressure on materials, creating problems that need repairing immediately.

Though stainless steel has various grades that are more suitable for even the harshest weather conditions, the strength of a material is dire when constructing buildings. So, architects choose this material for that reason.

It Acquires a Certain Strength-to-Weight Ratio

It’s essential for other industries, like aviation, to have specific numbers that determine a fair ratio between strength and weight. There’s one way to look at this more, and it’s through the different planes made in the last century. Military aviators seek strong materials that don’t corrode.

While they work with stainless steel, they deal with a lightweight material that doesn’t deteriorate. The machines won’t corrode or damage by inclement weather in the air or by just sitting in a hangar.

Stainless Steel Is Sustainable

Right now, industry leaders need to become sustainable. In hindsight, designers and developers must look toward materials that don’t harm the planet and the surrounding environment.

One of the greatest things about stainless steel is that it’s reusable, so workers can continue to break down and use the material repeatedly without an expiration date. Keep in mind that it’s still essential to maintain the material, even though it’s not needed as often for other materials.

It doesn’t Overheat or Crack From Freezing Temperatures

For a material to have better attributes than another, it must have some resistance to hot and cold temperatures. Without this type of protection, materials break down and potentially do more than corrode—they’ll sometimes shatter if it’s too cold or expands, which isn’t a good thing.

When metal expands from the heat, it creates an unstable foundation, causing the building to appear like it is tipping. When it comes to stainless steel, you won’t need to worry about this. Certain practices also prevent such circumstances, such as applying the correct finisher.

Doesn’t Require Daily Maintenance

You won’t need to maintain the material as often; stainless steel’s one material that requires very little work. Additionally, stainless steel has an additional layer that prevents spots and other blemishes from appearing. If something does appear, it’s easy to remove.

Stainless Steel Looks Aesthetically Pleasing

Stainless steel looks great in every setting; it looks even better on your following line of products or future airplanes. Whatever your fabrication project is, using stainless steel has many advantages you can’t ignore. Work with your designers to develop a list of things you need for your next production, and ensure stainless steel has made its way to the top of your list.

Stainless Steel Lasts a Long Time

The material you use should last, and stainless steel is the material that survives it all. Using stainless steel doesn’t only mean you have a stronger product, but also that you have items that last a long time. This material has outstanding strength and resilience—from an airplane to buildings and cookware. While the production and fabrication costs are a little higher than other materials, it’s still a matter of time before the results show that the higher price was well worth the material choice.

We’re sure that with the right amount of work, we can produce the best stainless steel products for your industry. As professionals in stainless steel manufacturing, we at Custom Manufacturing and Polishing Inc, we must ensure that every project is met with suitable materials and there are no oversights. Trust in us, and you’ll see your stainless steel fabrication project come to life. We believe that every dream project is achievable. Let us know about your manufacturing project today; we’re happy to help you in every way!