Finned Tube Panel Designs & Their Use in Heat Exchangers

Walk through any factory floor or energy plant, and you’ll find machines working nonstop to manage heat. What keeps them running smoothly is raw power combined with carefully engineered systems that move thermal energy where it’s needed most. Finned tube panel configurations give heat exchangers the ability to improve efficiency.

How Tube Panels Improve Performance

The effectiveness of a heat exchanger depends on the surface area available for heat to pass between fluids. Adding fins to tube panels increases this area, which leads to faster, more efficient energy exchange. Machinery can achieve greater output without expanding the physical size of the unit.

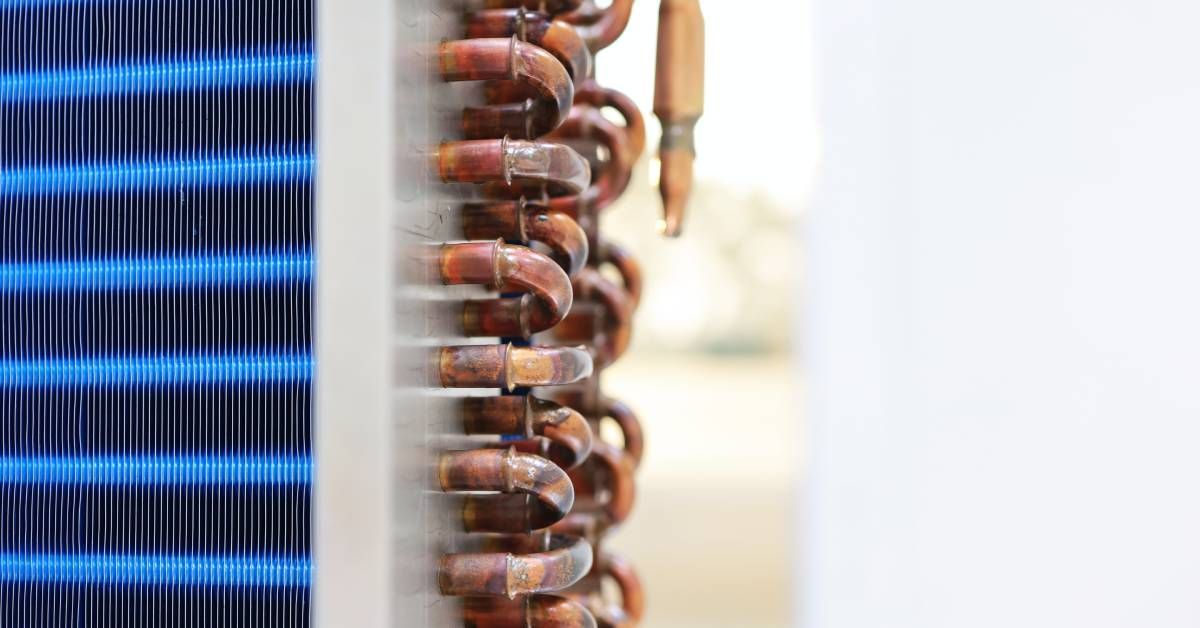

Finned tube panel designs come in several configurations, including longitudinal fins, spiral fins, and plate fins. Each type offers specific advantages depending on the application requirements and fluid properties.

Practical Applications in Various Industries

Heat exchangers are essential in multiple settings. Food and beverage professionals use them for cooling and pasteurization, while chemical plants depend on them to maintain exact reaction temperatures. Even large-scale climate control systems rely on their efficiency.

Finned tube panel designs have uses in high-performance heat exchangers. Because these panels enhance heat transfer, they help workers maintain temperatures in facilities.

Customization With Durable Materials

A major strength of modern tube panel systems is their adaptability. Depending on the operating environment, you can construct panels with different metals, coatings, and fin arrangements. For example, copper offers exceptional thermal conductivity for HVAC systems, while corrosion-resistant alloys are favored in chemical plants.

A polished stainless steel tube is the ideal solution in many applications. It combines strength, durability, and resistance to corrosion, making it perfect for demanding industrial environments. Its polished finish also simplifies cleaning and reduces the likelihood of buildup, which can interfere with long-term performance.

Long-Term Value

Modern systems have heat exchangers with finned tube panels in their designs to increase energy savings. In many cases, the upfront investment in specialized designs pays for itself through operational savings. Better efficiency reduces stress on system components, the chance of breakdowns, and maintenance costs. Enhanced heat transfer also supports sustainability initiatives by lowering energy consumption.

A Smarter Choice

Heat exchangers may operate behind the scenes, but they are vital to productivity and safety. By incorporating advanced panel engineering and materials like stainless steel, companies gain performance, cost savings, and durability. Customized finned tube panel solutions are ideal if you’re seeking the balance between efficiency and resilience. Contact the CMPI team to learn more!