The Development of Stainless Steel Technology and Its Future

The narrative of stainless steel technology's invention and development is one that takes us back to the early 20th century. It is a story punctuated by remarkable discoveries and advancements, each forming a stepping stone toward the highly refined stainless steel industry we are familiar with today. If you want to learn about the development of stainless steel technology and what the future of the industry holds, join us as we take a closer look.

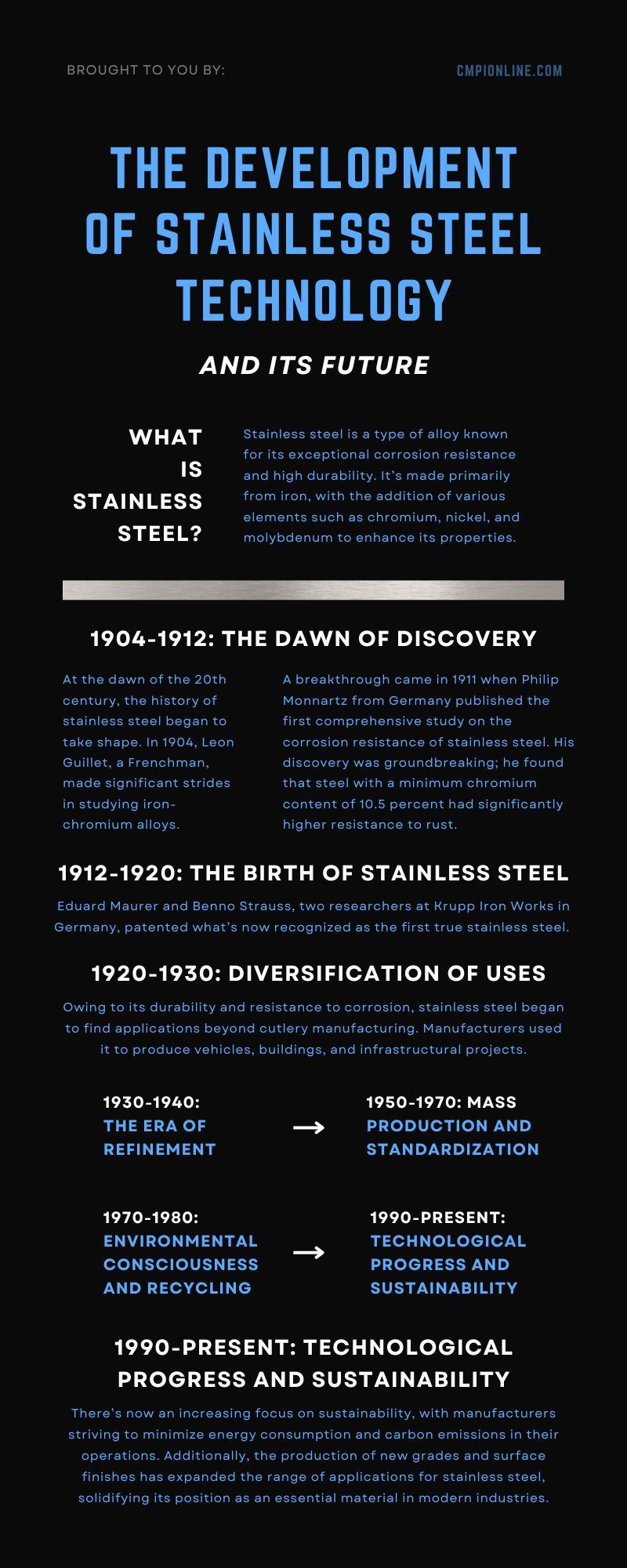

What Is Stainless Steel?

Stainless steel is a type of alloy known for its exceptional corrosion resistance and high durability. It’s made primarily from iron, with the addition of various elements such as chromium, nickel, and molybdenum to enhance its properties. The exact composition and ratio of these elements vary depending on the specific grade or type of stainless steel.

What Is Stainless Steel Used For?

Stainless steel's unique properties make it a versatile material that various industries utilize. Construction, architecture, and infrastructure commonly incorporate stainless steel due to its strength and resistance to rust and corrosion.

The automotive industry chooses stainless steel for its durability and aesthetic appeal in car parts, including exhaust systems, trimmings, and body panels.

The medical field heavily relies on stainless steel's sanitary and corrosion-resistant properties. Surgeons and healthcare professionals use stainless steel for surgical instruments, medical implants, and equipment to ensure safety and hygiene in healthcare facilities.

In the food industry, stainless steel is the preferred material for processing and packaging equipment due to its resistance to chemicals and bacteria. Additionally, stainless steel finds widespread use in household appliances like refrigerators, ovens, and dishwashers, thanks to its durability and sleek appearance.

Stainless Steel: Its Evolution Throughout the Years

Now that we have a basic understanding of what stainless steel is and its common uses, let's delve into its fascinating history. Here's a timeline of the key events and developments that have shaped stainless steel technology into what it is today:

1904-1912: The Dawn of Discovery

At the dawn of the 20th century, the history of stainless steel began to take shape. In 1904, Leon Guillet, a Frenchman, made significant strides in studying iron-chromium alloys. He diligently documented his findings but did not yet understand the relationship between chromium content and corrosion resistance. A breakthrough came in 1911 when Philip Monnartz from Germany published the first comprehensive study on the corrosion resistance of stainless steel. His discovery was groundbreaking; he found that steel with a minimum chromium content of 10.5 percent had significantly higher resistance to rust. This laid the groundwork for the developments to come.

1912-1920: The Birth of Stainless Steel

The year 1912 marked a significant milestone in the journey. Eduard Maurer and Benno Strauss, two researchers at Krupp Iron Works in Germany, patented what’s now recognized as the first true stainless steel. Their innovation was an alloy that combined 21 percent chromium and nickel, exhibiting unparalleled resistance to corrosion and acid. With this, the world witnessed the birth of stainless steel as we know it today.

1920-1930: Diversification of Uses

Following the birth of stainless steel, the 1920s saw a substantial expansion in its uses. Owing to its durability and resistance to corrosion, stainless steel began to find applications beyond cutlery manufacturing. Manufacturers used it to produce vehicles, buildings, and infrastructural projects. This decade also marked further advancements in stainless steel production technology, with manufacturers devising new methods to enhance efficiency and reduce costs.

1930-1940: The Era of Refinement

The subsequent two decades, the 1930s and 1940s, ushered in an era of refinement in stainless steel production. Researchers concentrated their efforts on improving methods to decarburize steel effectively while simultaneously preventing oxidation. During this period, stainless steel emerged as an indispensable material for constructing military equipment, marking a significant milestone in its evolution.

1950-1970: Mass Production and Standardization

The years between 1950 and 1970 heralded the era of mass production of stainless steel. Technological innovations enabled the manufacture of stainless steel on an unprecedented scale. A critical milestone was the introduction of the Argon Oxygen Decarburization (AOD) process, which facilitated the production of low carbon content stainless steel, thereby enhancing its corrosion resistance. Moreover, this period instigated the international standardization of stainless steel, ensuring uniformity in its production and quality worldwide.

1970-1980: Environmental Consciousness and Recycling

The 1970s and 1980s were characterized by a heightened awareness of environmental issues. In response, the stainless steel industry embarked on developing more eco-friendly production processes and emphasized the recyclability of stainless steel. Furthermore, the rise of duplex stainless steels, which amalgamate the beneficial properties of austenitic and ferritic steels, offered greater strength and improved resistance to stress corrosion cracking.

1990-Present: Technological Progress and Sustainability

In recent decades, the stainless steel industry has reaped the benefits of advancements in computer technology and automation. These innovations have led to more efficient and precise manufacturing processes. There’s now an increasing focus on sustainability, with manufacturers striving to minimize energy consumption and carbon emissions in their operations. Additionally, the production of new grades and surface finishes has expanded the range of applications for stainless steel, solidifying its position as an essential material in modern industries.

The Future of Stainless Steel

We’ve discussed the development of stainless steel technology throughout the years. But now you might wonder what its future holds.

The prospects for stainless steel technology appear promising. The demand for stainless steel continues to surge, fueled by its versatility and durability. Researchers are tirelessly working on developing new alloys and production methods to further enhance the properties of stainless steel and mitigate its environmental impact. The aim is to create high-performance stainless steels capable of withstanding extreme conditions, such as high temperatures and corrosive environments.

The Ongoing Growth of Stainless Steel Manufacturing

Today, the stainless steel manufacturing industry stands as a testament to its humble beginnings, having evolved and grown in tandem with continuous advancements in technology. CMPI , a leading stainless steel manufacturer, embodies the success and versatility of this remarkable material in the modern day. Offering a broad range of high-quality stainless steel products, including custom fabrication services, CMPI exemplifies the ongoing development of stainless steel technology. The future remains bright for stainless steel technology as it continues to play a pivotal role across various industries and in everyday life. As such, we eagerly await the next breakthroughs in this continually evolving field.