Top Benefits of Stainless Steel Piping in Construction

The construction industry constantly evolves to meet demands for sustainable and cost-efficient materials. Stainless steel piping offers benefits to construction professionals that support residential, commercial, and industrial projects.

Dive into the top benefits of stainless steel piping in construction so you can see why these pipes are the best option for architects and engineers.

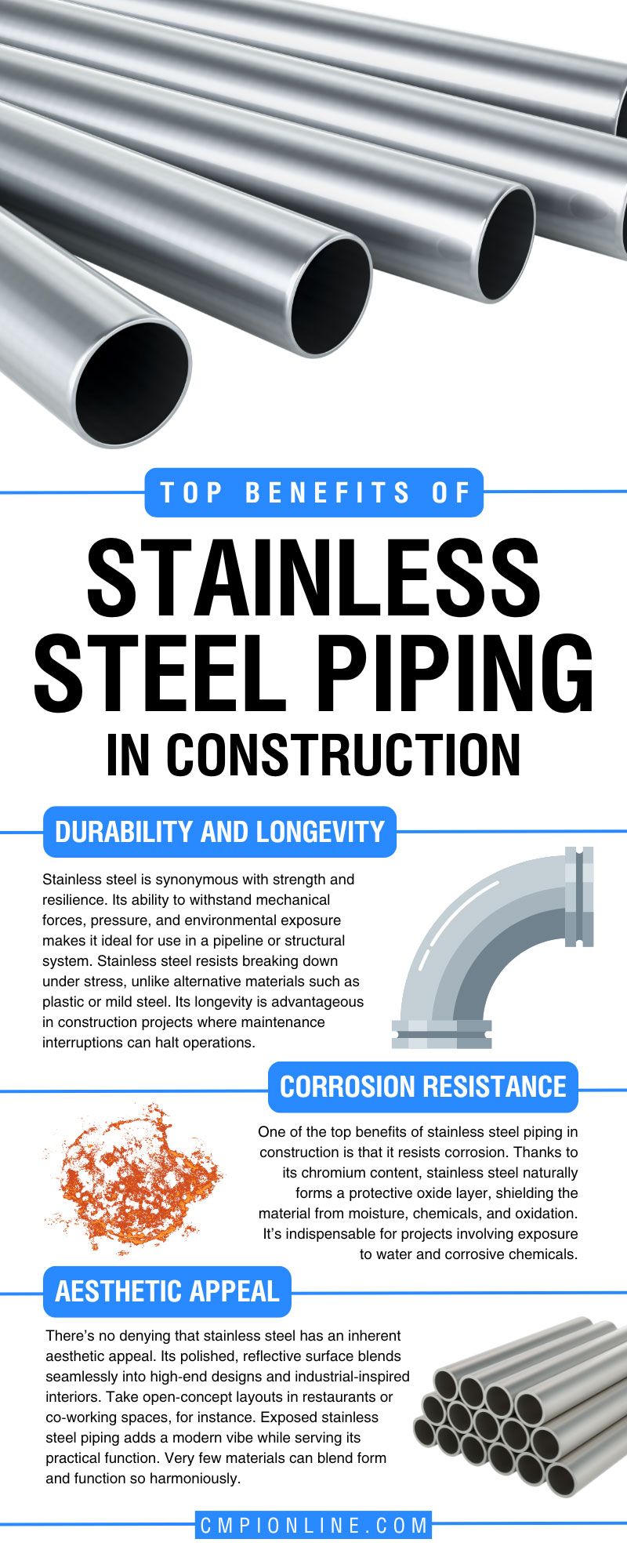

Durability and Longevity

Stainless steel is synonymous with strength and resilience. Its ability to withstand mechanical forces, pressure, and environmental exposure makes it ideal for use in a pipeline or structural system. Stainless steel resists breaking down under stress, unlike alternative materials such as plastic or mild steel. Its longevity is advantageous in construction projects where maintenance interruptions can halt operations.

Corrosion Resistance

One of the top benefits of stainless steel piping in construction is that it resists corrosion. Thanks to its chromium content, stainless steel naturally forms a protective oxide layer, shielding the material from moisture, chemicals, and oxidation. It’s indispensable for projects involving exposure to water and corrosive chemicals.

Sustainability and Eco-Friendliness

Sustainability is a focus for modern builders. Stainless steel aligns with this movement by being 100 percent recyclable, with little to no degradation during recycling. When you need to replace outdated systems or remodel structures, you can melt the stainless steel pipes and repurpose them into new materials. In addition, stainless steel is energy-efficient to produce and requires fewer replacements over time, further boosting sustainability credentials.

Aesthetic Appeal

There’s no denying that stainless steel has an inherent aesthetic appeal. Its polished, reflective surface blends seamlessly into high-end designs and industrial-inspired interiors. Take open-concept layouts in restaurants or co-working spaces, for instance. Exposed stainless steel piping adds a modern vibe while serving its practical function. Very few materials can blend of form and function so harmoniously.

Lightweight yet Strong

Stainless steel piping is relatively lightweight compared to other materials with similar strength and performance. This reduces stress on structural supports for piping while facilitating transportation and installation. It also makes stainless steel piping ideal for high-rise buildings because it minimizes the weight of the piping system.

Seismic and Fire Resistance

Stainless steel piping resists seismic activity due to the material’s inherent durability. In areas prone to earthquakes or other natural disasters, stainless steel pipes offer a reliable and stable alternative to traditional materials that may be more vulnerable to damage, such as PVC or galvanized steel. In addition, stainless steel pipes have a high melting point and do not emit toxic fumes if exposed to fire.

Hygienic and Non-Toxic Properties

Stainless steel is ideal for piping in sanitary facilities. The non-porous surface naturally resists bacterial buildup, making it much easier to clean and sanitize. Stainless steel is also popular for its non-toxic properties. Water supply systems consist of stainless steel pipes to ensure safe and contaminant-free water passage because these pipes won’t leach toxic chemicals.

Reduced Noise Levels

Stainless steel has a high density and low resonance properties, making it excellent for sound insulation. Architects use stainless steel to create a quiet environment in hospitals, schools, and concert halls.

Resistance to Abrasion

Steel pipes resist abrasion and wear, making them perfect for applications involving heavy machinery or the high-speed flow of liquids. This property also makes them ideal for use in instances when the pipes may come into contact with abrasive substances, such as sand or gravel.

Longevity and Low Maintenance

Stainless steel pipes have a longer lifespan than other materials, making them cost-effective. They can last up to 100 years without corroding or needing replacement. Additionally, stainless steel has low maintenance needs because it is not prone to rusting or corrosion.

Flexible Installation Options

Another benefit of stainless steel pipes is that they simplify installation. They’re compatible with innovative joining techniques, such as press-fit systems, supporting faster and cleaner installations. Stainless steel pipes also require fewer supports during installation.

Cost-Effectiveness Over Time

While stainless steel piping has a higher upfront cost than other materials, its low maintenance needs and long lifespan make it cost-effective. Reduced replacement needs, minimal maintenance, and long-term corrosion resistance save business leaders and contractors money in the long run.

Reduced Project Timelines

Using stainless steel piping simplifies installation and reduces labor intensity. Stainless steel is compatible with joining technologies such as press-fit, TIG welding, and mechanical couplings. This eliminates the need for complex and time-consuming fittings. These time savings can be valuable for large-scale projects with tight deadlines.

Moreover, stainless steel’s dimensional consistency and ease of fabrication also reduce the need for on-site modifications, helping teams avoid unexpected delays.

Supply Chain Stability

One of the most practical advantages of using stainless steel piping is its widespread availability. As a globally manufactured material with standardized grades and sizes, stainless steel is accessible through a wide network of suppliers. This makes it possible to meet project demands and accommodate last-minute design changes. When timelines are tight and coordination is key, reliable availability is just as important as durability or strength.

A Versatile Material for Diverse Applications

Stainless steel’s versatility makes it an excellent choice for countless applications across construction:

- Stainless steel’s strength, smooth finish, and resistance to thermal expansion work well in HVAC systems. They enable optimal airflow with reduced inefficiencies.

- You can use stainless steel for load-bearing or decorative piping.

- Stainless steel is common in specialized factories and chemical plants that require materials resistant to extreme temperatures or chemicals.

Tips for Selecting the Right Stainless Steel Piping Material

Choosing stainless steel isn’t the last piping decision you need to make. There are several other things to consider.

Understand Your Requirements

Evaluate pressure tolerance, environmental exposure, and the intended application before selecting stainless steel grades. For example, if you plan to use your piping system in a corrosive or high-temperature setting, consider using grades 316 or 321.

Choose Trusted Providers

Stainless steel may require surface finishing, such as electropolishing or passivation, to enhance its corrosion resistance and appearance. Luckily, you can collaborate with experts at Custom Manufacturing & Polishing, Inc. (CMPI) for optimal results.

Consider Sustainability Goals

Look for stainless steel with recycled content, or buy from providers with eco-conscious manufacturing processes. These actions contribute to a greener environment and demonstrate your company’s commitment to sustainability.

Stainless Steel Piping Is Leading the Way in Construction

When it comes to reliability, performance, and long-term value, stainless steel piping consistently outshines alternatives. It doesn’t matter if you’re designing an architecturally striking handrail or building a plumbing system; stainless steel is your answer for quality without compromise.

Does your latest project need steel piping? Partner with CMPI. We help construction professionals redefine excellence with our custom stainless steel fabrications. Call our team today to discuss your needs.