Types of External Jacketed Heat Transfer Surfaces

Temperature control is an important part of production processes across industries. For example, if a product that is meant to be kept extremely hot cools too much, it may be ruined and may become unusable. Using a heat exchange surface on a vessel is one way to solve this problem, as heat exchange surfaces help to regulate the temperature of a vessel and its contents. Read on to learn more about the different types of external jacketed heat transfer surfaces and what they are used for.

How Do They Work?

When a jacket is placed over a vessel, a cavity is created between vessel and jacket. This cavity can then be filled with a cooling or heating fluid that will help to regulate the temperature of the vessel. The jacket helps to circulate those cooling and heating fluids across the surface of the vessel, promoting heating and cooling throughout all the parts of the surface it covers.

Types of Jacketed Vessels

There are three main types of external jacketed heat transfer surfaces : conventional jackets, dimple jackets, and half-pipe coil jackets. In addition, internal coils can be used to regulate heat transfer, although they are not themselves a type of jacketed vessel. Here is a brief overview of each type of vessel and its uses.

Conventional Jacket

A conventional jacket is installed over a vessel to create the annular space that the cooling or heating medium flows through. This medium is typically a liquid substance like water, oil, or another fluid. In some designs, baffles are welded to the inside of the jacket to control the flow of the heating and cooling medium throughout the jacket and vessel. Conventional jackets are able to achieve the lowest pressure drop of all the jacket types. However, due to the lack of reinforcement in the design, conventional jackets tend to be thicker and more expensive than other jacket types.

Uses

Conventional jackets are typically used in applications that have a relatively low pressure, under 50 psi. They are generally used in smaller tanks that hold 100 gallons or less. However, in certain situations, they can also be used in higher pressure applications, particularly when the internal pressure of the vessel is double that of the jacket pressure.

Dimple Jacket

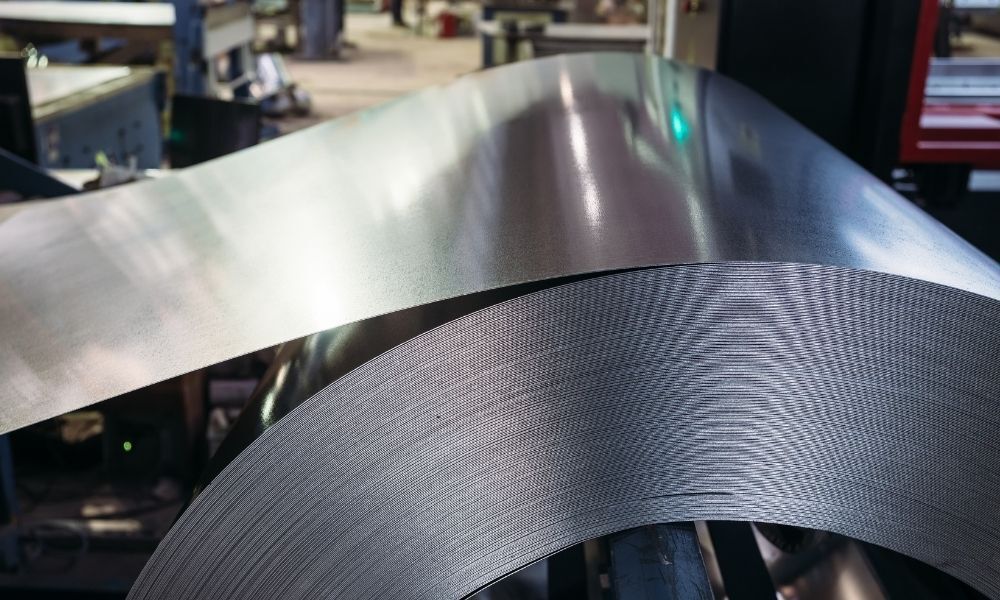

A dimple jacket is a type of jacket with divots, or dimples, across its surface. These dimples on the surface of the jacket promote heat transfer throughout the vessel by creating turbulence in the heating and cooling fluid of the vessel. Although their design is thinner than that of a conventional jacket, a dimple jacket is just as strong and less expensive, making it a universally popular choice.

Uses

Dimple jackets are manufactured in different shapes, sizes, and pressures, making them an incredibly versatile jacket choice since they can be used in much more than tanks. They are used to heat or cool large surface areas of vessels. Dimple jackets are approved for use in vessels with up to 300 psi. Dimple jackets should not be used in vessels that require thermal cycling, which is when the temperature of the tank cycles between extremely high and extremely low temperatures.

Half-Pipe Coil Jacket

A half-pipe coil jacket consists of a split pipe that is wound around and welded to the vessel, controlling the path of the heating and cooling fluid beneath the jacket. Half-pipe jackets can be used on the entirety of a vessel or only on specific parts. Because of their ability to use a lighter metal, these types of jackets are more expensive than dimple jackets, but not quite as expensive as conventional jackets.

Uses

Half-pipe jackets are best for applications that require a jacket with a high-pressure level, as half-pipe jackets are rated up to 750 psi. These types of jackets work well for applications that involve high temperatures and liquid heat transfer.

Internal Coil

Internal coils are not a type of jacketed vessel, but can be installed inside of vessels to aid with heat transfer. Unlike a jacket, an internal coil physically comes in contact with the product inside the vessel, since they are located within the vessel rather than externally. Internal coils circle the inside of a vessel in a spiral shape, or in some cases, they are simply located at the bottom of the vessel.

Uses

Internal coils have a pressure rating of up to 900 psi, higher than any of the jacket types. As such, they are useful within vessels that have a very high internal or external pressure. Internal coils are common in many industries and are used in applications whose products won’t corrode the metal of the coil.

Which Industries Use Jacketed Vessels?

Jacketed vessels are integral to the function of a wide number of industries. They help to keep products at their proper temperatures during the manufacturing process and can help with thermal cycling during the process as well. Below are just a few of the many industries that incorporate jacketed heat transfer surfaces into their equipment:

- Chemical

- Industrial Production

- Medical

- Food and Beverage

- Brewing

- Pharmaceutical

- Asphalt and Roofing

Which Jacketed Vessel Should You Choose?

The type of jacket that you should choose for your vessel depends largely upon the function of the vessel and the amount of pressure that the vessel will undergo. If your vessel will need to hit low pressures, a conventional jacket would be best since it is capable of maintaining these lows. If you can’t afford the generally higher price of a conventional jacket or need a type that can achieve a higher pressure, a dimple jacket or half-pipe coil jacket is a good choice. Dimple jackets are the most versatile of the three types and are a safe choice for most applications, provided your vessel won’t need to change temperatures frequently. For most industrial vessels that require very high pressures or temperatures, choose a half-pipe coil jacket, which can handle these highs.

Selecting the right type of jacket for your vessel is important, and we hope that this guide will help you to make your decision. Once you do, we hope you’ll consider using CMPI for your jacket and tank needs. We specialize in manufacturing dimple jacket heat transfer assemblies and other tank and vessel components. Give us a call and learn what CMPI can do for you.