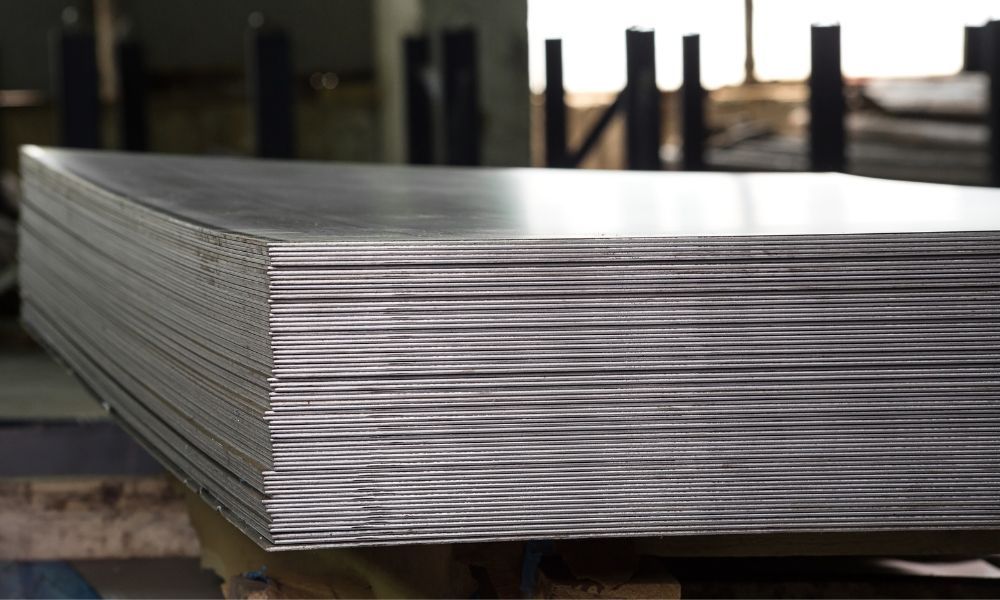

Ultimate Guide to Polishing Stainless Steel Sheets

While every business uses stainless steel, a select bunch may not know what goes into creating these versatile sheets. No matter what you plan to do with these sheets, we want to ensure that everyone understands how cleaning and maintaining them works. Here is the ultimate guide to polishing stainless steel sheets.

What’s the Benefit of Polishing Stainless Steel Sheets?

With many fields using stainless steel, industry workers may not know why their products begin to lose their luster. The reason stainless steel loses its sheen is age and lack of maintenance. It may seem like a contradiction since stainless steel is supposed to be a low-maintenance material that cuts down on your daily tasks. However, it’s still essential to maintain its shine even as it ages.

How could a distributor benefit from polished stainless steel? When entrusting a company to create sleek stainless steel sheets for your products, you’re guaranteed greatness, a team open to collaboration, and ensuring you get what you put in. Here are the benefits to expect:

- Polishing eliminates unwanted blemishes, residue, and other contaminants that few can see.

- Aesthetic is the number one thing merchants look for in their products. They want each piece to have a sophistication that lasts decades. It should be a timeless piece that attracts the eye.

- Polishing removes corrosion. While stainless steel has chromium, which increases corrosion resistance, it still experiences rust. Polishing metal often leads to improved chances of less corrosion.

How To Polish Stainless Steel Sheets

Polishing stainless steel is essential for longer-lasting products and increased durability. Continue exploring how to polish stainless sheets below in our three-step guide with helpful tips and answers to commonly asked questions.

Readying the Steel Sheets

In the polishing process, the first step is to clean the sheets so they’re ready for buffing or sanding. In this step, focus on fixing damaged or rough spots. These spots, if left untouched, could lead to malformed products at the end-user phase. Ensuring you do this step first, above all else, improves attention to detail and ensures the sheet is finished accordingly.

How To Fix Damaged Areas

If you have metal that’s spotty, has rough patches, and might have corrosion, you have extra work to do. These areas can affect the final product, so taking care of them first is critical. Using a grit brush of 80 to 120, go over the rough areas. You may want to do it a second time to ensure you’ve smoothed it out and gotten rid of blemishes.

How To Clean the Metal

When cleaning the metal, ensure you have the right supplies before or after you’ve worked on the rough or damaged parts. Your inventory list must include a grinder—bench or angle—a buffer and pad, acetone, sponges—ensure the sponges are soft—polishing compound, and white vinegar.

Each item you need has a purpose, such as the acetone. You use acetone to clear away sticky deposits—it’s a lot like rubbing alcohol. When wiping the surface with soap and water, use the sponge first to soak the area, then wipe the soap and debris away with a cloth. Do not start buffing until the sheet is completely dry.

Buffing the Sheets

Ensure the sheets are dry before buffing. Not waiting until the surface is dry could smear the finisher used in the final step, leading to a lustreless shine. Instead of smooth finishes, the smearing may resemble pinwheels at the end of the cleaning process. So wait for the surface to dry, then start this process.

Is Buffing Stainless Steel Necessary?

Buffing is necessary if you want stainless steel to maintain its beautiful luster. This step is always necessary if keeping a shimmery, mirror-like appearance is the daily goal. Say that all maintenance does to maintain stainless steel is apply oil. While oil does help, it dries and wears fast, leading to a continuous buildup of residue in the crevices.

To best avoid persistent issues later, make a daily habit of buffing instead of only applying oil to every stainless steel surface in the building. While it can be hard to keep up with this task, here are tips to help make the buffing process smoother today and in the future.

Tips for Better Buffing

One of the best ways to maintain metal sheets is by buffing them. You won’t end up with a clean appearance every time, but you can improve your polishing practices by following these tips:

- Don’t force the buffer wheel down too hard. Gently brush over the surface; when you’re gentle, the results are better.

- Avoid using the same wheel or cloth for every compound. Using the same one could alter the effects of the finish.

- Try not to use too much compound. Using too much lowers your inventory, and it runs out faster. Additionally, it doesn’t make a difference in how shiny your surface gets.

- Don’t go too slow; stay on one spot for one to two seconds, then move on to the next spot.

Polishing the Sheets

Polishing is the fun part, and it’s not as strenuous as buffing. All you need are your own two hands or another buffing wheel. Using your hands or a buffing wheel or pad can deliver the finishing touches to your piece. Machine polishing and hand polishing are two of the best methods for cleaning stainless steel sheets.

Machine Polishing

This process involves buffing. Since it’s already done in the second step, take the time to analyze the surface. Does it show imperfections, like a streak or a spot you completely missed? Go ahead and do a second round, but in that one area. If you missed multiple places, divide up the work and focus on one place at a time.

Going over again with a new buffing wheel or pad can help improve your skill in building a smoother surface next time. If buffing isn’t something you want to do, try hand polishing instead. This method works just as well, but you use a cloth and your hands.

Hand Polishing

Hand polishing is a process to keep in your back pocket. This method allows you to get your hands dirty—literally. However, cleaning with your hands might not be suitable for larger pieces, like long roof sheets or signs. Put this method aside for smaller projects, like appliances or machine parts.

Polish Your Stainless Steel With CMPI

Having a team of professional stainless steel fabricators on your side is all you need to learn how to polish stainless steel sheets. Continue collaborating and doing great things with Custom Manufacturing and Polishing, Inc. We believe in creating any idea that comes to mind.

CMPI is a team of dreamers aspiring to create items that meet expectations for all clients. One essential thing you’ll get from us is competency from a team of hard workers with the experience to create polished stainless steel panels to your expectations. Come discover what we’re offering by contacting us for a free quote.