How Steel Contributes to Energy Efficiency in HVAC Systems

The heating, ventilation, and air conditioning (HVAC) industry is evolving, driven by growing demands for energy efficiency and sustainability. With the heightened focus on reducing carbon footprints and optimizing performance, the strategic use of steel is playing a pivotal role in modern HVAC systems. This guide explores how steel contributes to energy efficiency in HVAC systems. We’ll discuss its properties, applications, and the improvements it brings to sustainability and efficiency.

The Material Advantage: Why Steel Matters in HVAC

Steel is a foundational material in the construction and HVAC industries, prized for its durability and structural strength. When used strategically in HVAC applications, steel delivers multiple energy efficiency benefits, including the following:

- excellent heat transfer properties for both heating and cooling systems

- high structural integrity that allows thinner walls and reduced material use

- superior corrosion resistance, extending the system’s operational life

- tight manufacturing tolerances that prevent leakage and thermal inefficiencies

The precision and quality of steel components can significantly impact an HVAC system’s performance.

Steel Tubing: The Backbone of Efficient Airflow

Tubing is one of the most critical components in any HVAC setup. It carries heated or cooled air, refrigerants, or water across the system’s parts. The efficiency of this transfer depends heavily on the quality of the tubing. Here’s where steel tubing offers an edge.

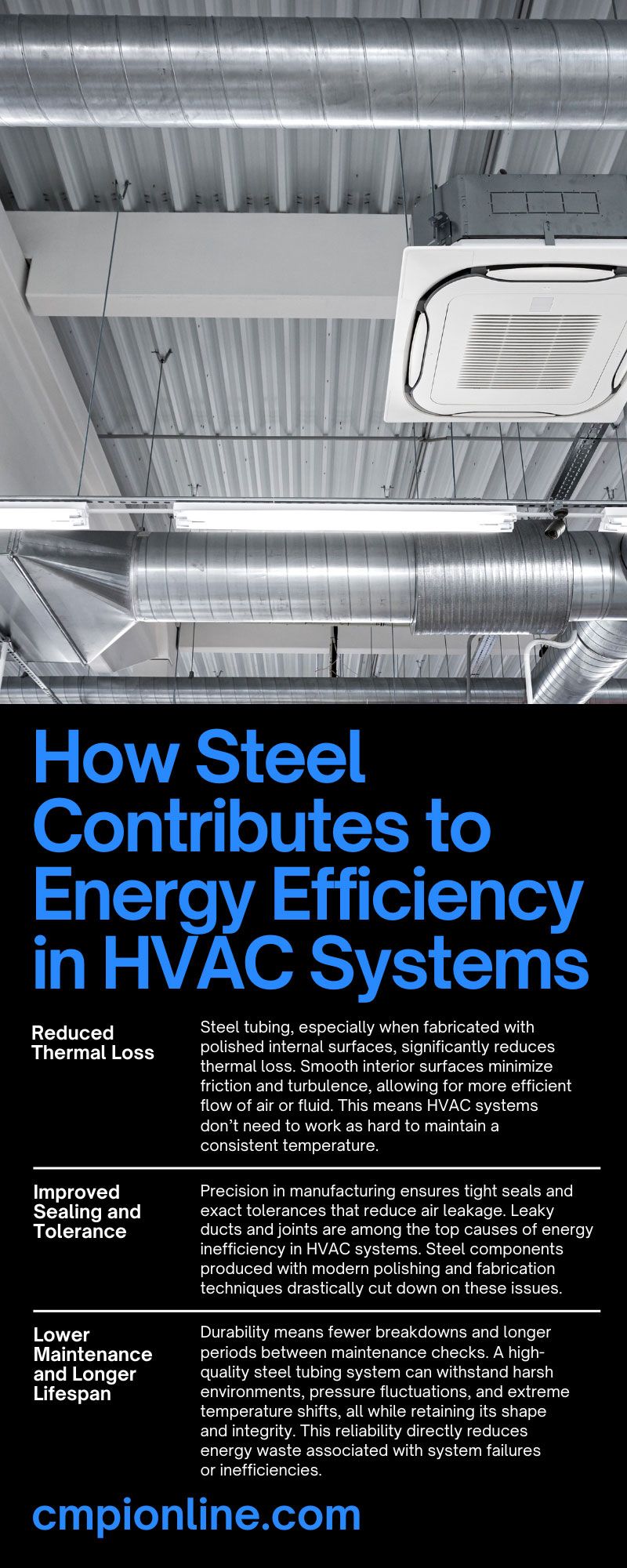

Reduced Thermal Loss

Steel tubing, especially when fabricated with polished internal surfaces, significantly reduces thermal loss. Smooth interior surfaces minimize friction and turbulence, allowing for more efficient flow of air or fluid. This means HVAC systems don’t need to work as hard to maintain a consistent temperature.

Improved Sealing and Tolerance

Precision in manufacturing ensures tight seals and exact tolerances that reduce air leakage. Leaky ducts and joints are among the top causes of energy inefficiency in HVAC systems. Steel components produced with modern polishing and fabrication techniques drastically cut down on these issues.

Lower Maintenance and Longer Lifespan

Durability means fewer breakdowns and longer periods between maintenance checks. A high-quality steel tubing system can withstand harsh environments, pressure fluctuations, and extreme temperature shifts, all while retaining its shape and integrity. This reliability directly reduces energy waste associated with system failures or inefficiencies.

The Role of Polishing and Surface Finishing

The performance of HVAC components can vary widely based on the surface finish of the materials you use. That’s why CMPI specializes in advanced polishing techniques that improve appearance and function.

A smoother finish leads to these benefits:

- better airflow with less resistance

- reduced bacterial growth and contaminant buildup in air ducts

- enhanced corrosion resistance, particularly in coastal or humid environments

These surface enhancements directly improve energy efficiency. Clean, smooth tubes maintain peak performance longer and require less energy to push air or liquid through the system.

Fabrication Precision = Energy Efficiency

The fabrication process itself plays a massive role in the energy footprint of an HVAC system. Poorly fabricated tubing can introduce inefficiencies that sabotage even the best system designs. From bending and welding to polishing and final assembly, each step must meet strict standards to ensure performance.

At CMPI, custom steel tubing fabrication allows engineers and HVAC professionals to tailor solutions to specific project needs. Precision-built tubing ensures an optimal balance of flow rate, durability, and energy use for compact systems, large-scale commercial installations, and everything in between.

Because no two HVAC systems are exactly alike, custom fabrication ensures the components work in harmony. Systems designed with this level of detail often demonstrate better performance and longer service lives than those built from off-the-shelf parts.

Application Examples: Where Steel Makes a Difference

Steel’s role in HVAC efficiency becomes clear when looking at real-world applications. Here are several scenarios where steel makes a measurable difference.

Commercial Rooftop Units

Rooftop HVAC units endure extreme temperature fluctuations and constant exposure to the elements. Stainless steel tubing, with its corrosion resistance and structural integrity, withstands these harsh conditions without degrading performance. Its durability ensures consistent airflow and minimal thermal loss, which translates into lower energy bills for large commercial spaces.

Clean Rooms and Hospitals

In medical and laboratory environments, air purity and temperature control are nonnegotiable. Polished steel ductwork minimizes particulate buildup and microbial contamination, supporting strict indoor air quality standards. At the same time, smooth, corrosion-resistant surfaces enhance airflow efficiency, enabling these systems to meet performance goals with reduced energy input.

High-Rise Buildings

Tall structures present unique challenges, such as pressure drops in vertical duct runs and inconsistent airflow across multiple floors. Steel tubing provides the strength and precise tolerances needed to maintain efficient operation across long distances. By reducing energy losses caused by friction and leakage, steel helps high-rise HVAC systems deliver consistent climate control throughout the building.

Industrial Process HVAC

Industrial facilities often rely on HVAC systems to manage both comfort and operational needs, such as heat exhaust and cooling for machinery and equipment. In these settings, steel tubing must handle high temperatures, pressure variations, and exposure to chemicals or particulates.

Sustainability Beyond Efficiency

While steel’s energy-saving benefits in HVAC systems are substantial, its contribution to sustainability extends far beyond day-to-day efficiency. One of steel’s greatest environmental strengths lies in its recyclability.

Unlike many other building materials that degrade or lose quality over time, you can recycle steel repeatedly without compromising its structural integrity. This means that even after decades of service in an HVAC system, steel components are recoverable and can be melted down and repurposed into new products. This recyclability reduces the need for virgin material extraction and lowers the overall carbon footprint of construction projects.

Choosing the Right Steel Partner

To see for yourself how steel contributes to energy efficiency in HVAC systems, it’s essential to collaborate with experts in steel fabrication and manufacturing. Trusted manufacturers such as CMPI combine precision, expertise, and innovative techniques to deliver tailored solutions for even the most complex HVAC challenges.

Whether you require polished components, heat transfer systems, or structural solutions, CMPI offers comprehensive services to support your goals.

Empowering Energy Efficiency With Steel

The HVAC industry’s pursuit of energy efficiency relies heavily on material innovation, and steel remains the preferred choice for manufacturers and engineers. By leveraging steel’s unique properties and integrating it into key components, such as ducts, coils, and piping systems, HVAC systems can achieve lower operational costs and a reduced environmental impact.