How Uniflow & Coil Jackets Affect Thermal Performance

In demanding industrial applications, precise temperature control is a fundamental requirement. Inefficient industrial thermal management leads to inconsistent product quality, extended processing times, and increased operational costs. Understanding the technology behind vessel heating and cooling can optimize these processes. Two prominent designs, Uniflow jackets and coil jackets, offer distinct solutions for managing thermal performance in stainless steel vessels.

These systems provide efficient and uniform heat transfer, which is necessary for industries ranging from pharmaceuticals to food and beverage. Evaluating how Uniflow and coil jackets affect thermal performance helps you select the most effective solution for your specific application. This article will explore the mechanics, benefits, and considerations of each system to guide you in your decision-making process.

The Role of Thermal Performance in Industrial Processes

Efficient thermal performance maintains process integrity and product quality. The ability to heat or cool a vessel's contents quickly and evenly directly impacts batch consistency and production throughput. Inconsistent temperature distribution results in hot or cold spots, leading to subpar product outcomes and potential waste.

Optimized heat transfer reduces the energy required to maintain desired temperatures, lowering operational expenses. When you select the right jacket design, you improve the efficiency of your operations, reduce cycle times, and achieve more predictable results batch after batch.

Understanding Conventional Jacket Designs

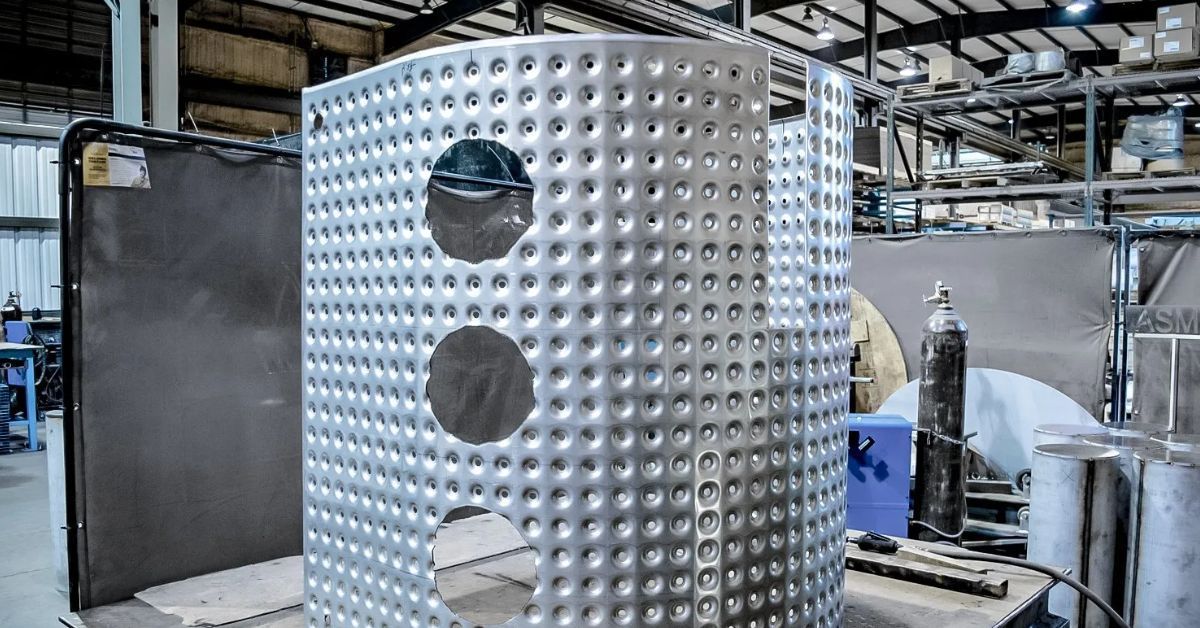

Traditional jacketed tanks, such as dimple or standard channel wall jackets, are common in many industries. These systems circulate a heating or cooling medium through an outer layer surrounding the vessel. While functional, they have inherent design limitations that compromise performance.

These conventional designs allow for the formation of air gaps and irregular flow paths for the thermal medium. This leads to the path of least resistance being followed, causing inconsistent heating and cooling across the vessel's surface and impacting the final product.

What Is a Uniflow Jacket?

A Uniflow jacket is an advanced thermal management system featuring a continuously welded, tightly wound stainless steel coil on the vessel's exterior. This design forces the heating or cooling medium, such as steam or water, to travel in a single, high-velocity direction from the inlet to the outlet.

This unidirectional flow is the innovation that separates it from conventional designs. It systematically eliminates the air gaps and irregular flow patterns that cause temperature inconsistencies, creating a uniform distribution of heat across the entire transfer surface.

How Uniflow Jackets Improve Heat Transfer

The Uniflow design improves thermal efficiency by maximizing the heat transfer surface area. The specialized coil geometry allows for a thinner interior vessel wall, which accelerates the rate of heating and cooling. This results in faster, more responsive temperature control throughout the process cycle.

Tests show that this innovative approach substantially reduces total processing time compared to standard jackets. As a result, operators can complete more batches in the same amount of time, directly improving throughput and operational capacity.

Exploring Coil Jacket Systems

Coil jackets, or submerged coils, represent another effective method for indirect heating and cooling. This system involves placing a series of pipes or coils directly within the process fluid inside the vessel. This direct contact creates rapid and aggressive temperature changes.

Coils are particularly effective for processes that demand quick thermal adjustments. Many use them for highly viscous fluids like oils, syrups, or molasses, where efficient heat penetration lowers viscosity and allows for easier handling.

Performance Factors of Coil Jackets

Several factors influence how a coil jacket performs, including the velocity of the thermal medium, the coil material, and the properties of the process fluid. Agitation or stirring within the vessel creates forced convection, which increases the heat transfer coefficient.

You also need to consider design. Very long, continuous coils experience pressure drops, leading to temperature gradients along their length. At low flow rates, coils are susceptible to fouling, where deposits build up on the surface and inhibit heat transfer. Implementing regular cleaning schedules and using high-quality thermal mediums reduces fouling, creating consistent performance and extending the system's lifespan.

Achieving Uniform Temperature Distribution

Any processes that demand the highest level of consistency require uniform temperature distribution. Uniflow jackets excel in this area by preventing hot and cold spots. The single-direction, high-velocity flow covers every part of the vessel wall with consistent thermal exposure.

While coils offer aggressive heating, they don't provide the same level of evenness, especially in large or unstirred tanks. The choice between systems depends on whether the process prioritizes speed of temperature change or absolute uniformity. This level of uniformity is necessary in industries like pharmaceuticals and food processing, where even minor temperature changes compromise product quality and safety.

Durability and Maintenance Considerations

Industrial environments require strong systems, and both Uniflow and coil jacket designs meet that challenge. Their construction directly influences long-term durability and maintenance requirements. Engineers design Uniflow coils to withstand rapid temperature fluctuations, which extends their service life.

Coil jackets, particularly in applications with poor-quality steam or low flow rates, are more prone to issues like waterlogging or fouling. Proper drainage and regular maintenance prevent condensate buildup, which can cause noise, vibration, and corrosion.

Selecting the Right Solution for Your Application

Choosing between a Uniflow and a coil jacket depends on your specific operational requirements. If your process demands precise, uniform temperature control and maximum throughput, the advanced design of a Uniflow jacket offers clear advantages.

If your primary need is for rapid and aggressive heating or cooling of viscous materials, a coil jacket system is more suitable for your situation. A thorough analysis of your process goals, fluid characteristics, and production schedule will help determine the best solution.

Partner With Experts for Custom Solutions

Thermal performance optimization enhances product quality, increasing throughput and reducing operational costs. Understanding how Uniflow and coil jackets affect thermal performance helps you choose the most effective solution. Both systems offer powerful benefits, but their impact varies depending on the design and the specific needs of your application. By grasping the core principles of each, you can make an informed decision that aligns with your production goals.

At Custom Manufacturing & Polishing, Inc., we specialize in fabricating custom stainless steel solutions, including advanced heat transfer systems that fit your exact specifications. Our expertise gives you a high-performance vessel engineered for reliability and efficiency. Contact us today to discuss your project and learn how our custom stainless steel fabrication services can improve your operations.