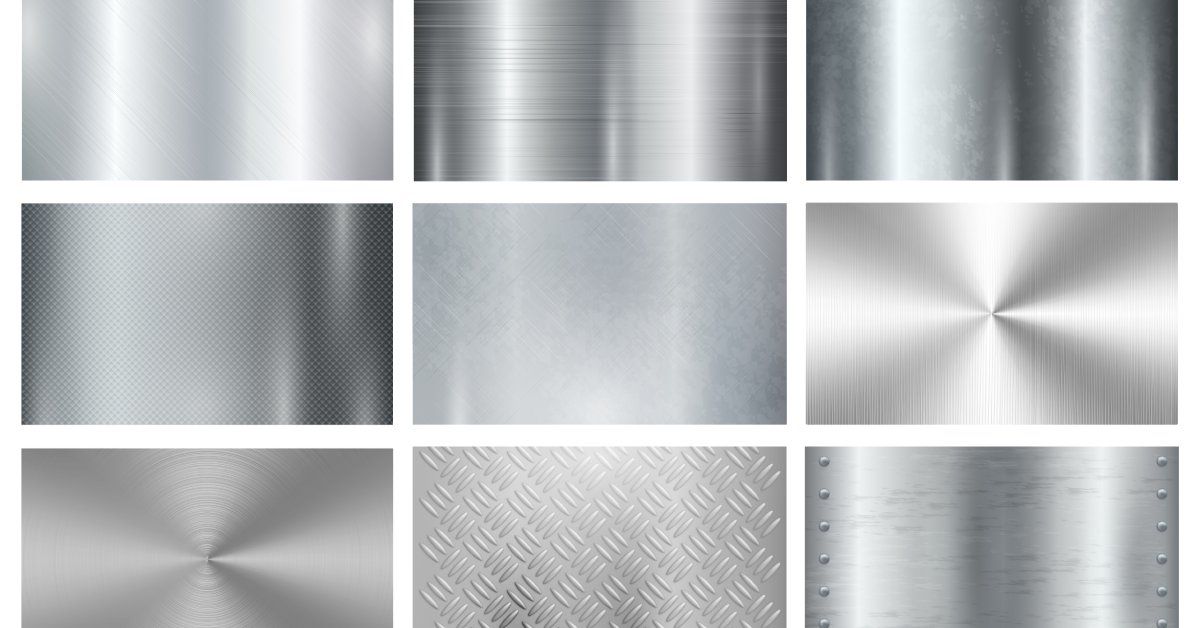

Pros and Cons of Brushed, Bead Blast, and Mirrored Finishes

Choosing the right finish for a stainless-steel project requires you to think about the finish’s durability, maintenance requirements, and overall cost. For general contractors, distributors, and designers, understanding these differences delivers a final product that meets client expectations for both form and function. This guide explores the pros and cons of brushed, bead blast, and mirrored finishes to help you make a confident choice for your next custom stainless-steel fabrication or architectural project.

Brushed Finish: The Practical Standard

A fine-bristle brush or belt abrades the steel's surface in one direction to create a brushed stainless-steel finish. This process results in a pattern of very fine, uniform lines, creating a satin-like, non-reflective appearance. The texture conceals minor imperfections, fingerprints, and small scratches, making it a practical choice for high-traffic areas and applications like kitchen appliances and architectural panels.

While its ability to hide wear is a major advantage, the micro-grooves require proper cleaning since the finish can trap moisture and contaminants that lead to corrosion. Deep gouges are challenging to repair, as they require re-brushing the entire surface.

Bead Blast Finish: Uniformity and Subtlety

High-pressure propulsion of fine media, like glass beads, strikes the steel surface to produce a bead blast finish. This technique removes surface imperfections and creates a smooth, non-directional, and uniform matte texture. The result is a soft, satin appearance that has glare reduction and a consistent, clean look across large surfaces, such as in architectural installations or for custom equipment housings.

The main drawback to a bead blast stainless steel finish is its susceptibility to showing fingerprints and oils. The fine texture, while visually appealing, also holds onto dirt and requires more frequent and thorough cleaning. Although it provides a sophisticated look, this finish is best for low-contact areas.

Mirrored Finish: High-Impact Aesthetics

A mirrored finish is the highest level of mechanical polishing, creating a smooth, highly reflective surface that has no visible texture. This process produces a striking visual effect and increases the steel's natural corrosion resistance by smoothing out the microscopic peaks and valleys. This makes it an excellent choice for decorative features, reflective signage, and high-end interior elements where you want visual impact.

The perfection of mirrored stainless steel is also its greatest liability. The flawless, glossy surface makes every scratch, smudge, and fingerprint highly visible, which requires frequent maintenance to preserve its appearance. The labor-intensive polishing process makes it the most expensive option among the three. Use it in protected or decorative applications where you can preserve its beauty without damage from heavy use or harsh conditions.

Making Your Decision

When you carefully consider the pros and cons of brushed, bead blast, and mirrored finishes for your project's aesthetic goals, durability, and maintenance needs, you set yourself up for success. For expert advice and custom solutions, like a polished stainless-steel plate or a high-end interior design element that uses mirrored stainless steel, reach out to Custom Manufacturing & Polishing, Inc.